Picking the right brass plumbing fittings for your home might seem like a small task, but it’s a big deal. These little connectors play a huge role in keeping your plumbing system running smoothly. Whether you’re fixing a leaky pipe or setting up a new bathroom, choosing the right fittings can save you a lot of time and headache down the road. In this guide, we’ll break down everything you need to know about brass fittings, from their types and benefits to common mistakes to avoid. Let’s dive in and make sure you get the best fit for your home.

Key Takeaways

- Brass fittings are essential for durable and corrosion-resistant plumbing systems.

- There are various types of brass fittings, each suited for specific applications.

- Choosing the right size and type of fitting is crucial to prevent leaks and ensure efficiency.

- Avoid common mistakes like mismatched threads and low-quality materials.

- Proper installation and maintenance can extend the life of your brass fittings.

Understanding Brass Plumbing Fittings

What Are Brass Plumbing Fittings?

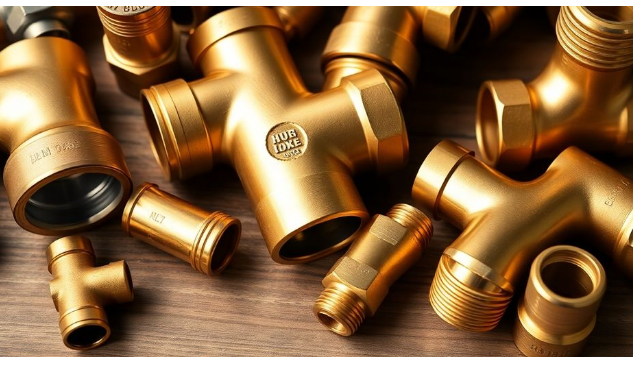

Brass plumbing fittings are essential components made from a copper-zinc alloy, known for their robust nature and ability to withstand high pressure. These fittings are vital for connecting pipes and controlling fluid flow in various systems, including water, gas, and HVAC setups. Their durability and resistance to corrosion make them a top choice for many plumbing applications. They come in different shapes and sizes, designed to meet specific needs and ensure a leak-proof seal.

Key Features of Brass Plumbing Fittings

When it comes to brass fittings, several key features stand out:

- Durability: Brass fittings can endure harsh conditions without breaking down, making them suitable for both residential and industrial uses.

- Corrosion Resistance: Unlike other metals, brass doesn’t rust easily, ensuring long-lasting performance in water systems.

- Versatility: These fittings are compatible with various materials, such as copper, plastic, and steel, making them adaptable to different plumbing needs.

Common Applications of Brass Plumbing Fittings

Brass fittings are used in a wide range of applications:

- Plumbing Systems: They are commonly used in water distribution systems to connect pipes and prevent leaks.

- Gas Lines: Brass fittings are ideal for gas systems as they can handle high pressures and temperatures without failing.

- Automotive Industry: In vehicles, brass fittings are used in fuel lines and cooling systems due to their strength and resistance to corrosion.

- Industrial Uses: They are also found in hydraulic systems and HVAC units, where they help control fluid movements efficiently.

Brass fittings are the unseen heroes in many systems, quietly ensuring everything runs smoothly. With their unique properties, they offer reliability and peace of mind, whether in a home or industrial setting.

Types of Brass Plumbing Fittings

Compression Fittings

Compression fittings are a popular choice for connecting pipes without the need for soldering. They work by compressing a brass ring onto the pipe, creating a tight seal. This makes them ideal for DIY enthusiasts who want a straightforward solution. These fittings are often used in applications where disassembly and reassembly are necessary, such as in water supply lines and some gas lines. Key advantages include ease of installation and the ability to withstand moderate pressure levels.

Flare Fittings

Flare fittings are typically used in high-pressure applications, such as gas lines or HVAC systems. They consist of a cone-shaped end that fits into a flared pipe, ensuring a leak-proof connection. The installation requires a special flaring tool, but the result is a very secure and reliable joint. Flare fittings are known for their durability and are often chosen for their ability to handle high-pressure environments safely.

Threaded Fittings

Threaded fittings are one of the most versatile types of brass fittings. They come with internal or external threads, allowing them to be screwed onto pipes or other fittings. This type of fitting is commonly used in plumbing and industrial applications due to its strength and ease of use. Threaded fittings offer flexibility, as they can be easily replaced or adjusted without cutting the pipe. When using threaded fittings, it’s essential to ensure thread compatibility to avoid leaks or damage.

Benefits of Using Brass Plumbing Fittings

Durability and Strength

Brass plumbing fittings are known for their exceptional strength. This makes them perfect for handling high-pressure situations without cracking or breaking. You can count on them to last a long time, even in tough conditions. Whether it’s the fluctuating temperatures of hot water systems or the constant pressure in a busy household, brass fittings are built to withstand it all.

Corrosion Resistance

One of the standout features of brass is its resistance to corrosion. Unlike some other metals, brass doesn’t rust. This quality is especially important in plumbing, where fittings are constantly exposed to moisture. With brass, you won’t have to worry about your fittings deteriorating over time. They maintain their integrity, ensuring that your plumbing system remains leak-free and reliable.

Versatility and Compatibility

Brass fittings can be used with a variety of materials, including copper, plastic, and steel. This versatility makes them a great choice for many different plumbing setups. They easily adapt to different pipes and systems, saving you the hassle of finding the right match. Plus, their compatibility means you won’t need special tools or skills to get them installed correctly.

Choosing brass fittings for your plumbing needs means investing in a reliable and long-lasting solution. Their strength, resistance to corrosion, and ability to work with different materials make them a top choice for any home.

How to Choose the Right Brass Plumbing Fittings

Assessing Your Plumbing Needs

Before diving into the world of brass fittings, take a moment to understand your specific plumbing requirements. Are you working on a water line, gas pipeline, or something else? Each application may demand a different type of fitting. Knowing exactly what you need will save you time and money in the long run. Consider whether the fitting will be exposed to chemicals, high temperatures, or pressures. These factors will guide you in choosing fittings that won’t fail under your system’s demands.

Considering Size and Compatibility

Size really does matter when it comes to fittings. Make sure you measure the pipe diameter accurately. A fitting that’s too small or too large can lead to leaks or even pipe bursts. It’s not just about the diameter; thread type and connection method are equally crucial. Compatibility with existing plumbing is key. If you’re unsure about the right size or type, don’t hesitate to consult a professional or refer to choosing the right pipe fittings for more detailed guidance.

Evaluating Pressure and Temperature Ratings

Not all brass fittings are created equal. Some are designed to handle higher pressures and temperatures than others. Check the ratings on the fittings to ensure they match your system’s requirements. Using a fitting with a lower rating than needed could lead to dangerous failures. Always err on the side of caution and choose fittings that can handle a bit more than your system’s maximum pressure and temperature.

When choosing brass plumbing fittings, it’s not just about picking something off the shelf. Consider the specific needs of your setup, and don’t skimp on quality. A fitting that fails can cause significant damage and costs, so choose wisely.

Common Mistakes to Avoid When Selecting Brass Plumbing Fittings

Ignoring Thread Compatibility

One of the biggest mistakes you can make is not paying attention to thread compatibility. When the threads of fittings and pipes don’t match, it’s a recipe for disaster. This mismatch can lead to leaks and a failure to seal properly, causing potential water damage and costly repairs. Always double-check the thread type before purchasing.

Overlooking Environmental Conditions

Environmental factors play a significant role in the longevity of brass fittings. Ignoring these conditions, like temperature, humidity, and exposure to chemicals, can lead to premature wear and tear. For instance, if you’re installing fittings in a high-humidity area, consider the risk of corrosion and choose fittings accordingly.

Choosing Low-Quality Fittings

Opting for cheap, low-quality fittings might save you a few bucks upfront, but it can cost you more in the long run. These fittings are often less durable and more prone to failure. Investing in high-quality brass fittings ensures a longer lifespan and fewer issues down the road. Remember, quality often correlates with reliability.

When selecting brass fittings, consider future costs and potential problems. Spending a bit more now can save a lot of hassle and money later. Don’t let initial savings cloud your judgment.

Quick Tips to Avoid Mistakes:

- Match the Threads: Always ensure thread types match between fittings and pipes.

- Consider the Environment: Choose fittings that can withstand the specific environmental conditions of your installation site.

- Prioritize Quality: Don’t compromise on quality for cost. Reliable fittings are worth the investment.

Installation and Maintenance Tips for Brass Plumbing Fittings

Proper Installation Techniques

Installing brass plumbing fittings correctly is crucial to avoid leaks and ensure longevity. First and foremost, make sure you have the right tools on hand—like adjustable wrenches and pipe cutters. Here’s a simple step-by-step guide to help you:

- Clean the Pipes: Before you begin, clean the pipes and fittings. Use a wire brush or sandpaper to remove any corrosion or debris. This will ensure a tight seal and prevent leaks. For more on cleaning techniques, check out how to fix a pinhole leak in a brass fitting.

- Use Sealants: Apply thread seal tape or pipe dope to threaded fittings to ensure a leak-proof connection. Wrap the tape clockwise around the threads to avoid unraveling when tightening.

- Tighten Carefully: Hand-tighten the fittings first, then use a wrench for the final turn. Be cautious not to overtighten, as this can damage the fittings and cause leaks.

Routine Maintenance Practices

Regular maintenance can extend the life of your brass fittings and prevent costly repairs. Here’s what you should do:

- Inspect Regularly: Check your fittings periodically for signs of wear or corrosion. This allows you to address small issues before they become big problems.

- Tighten Connections: Over time, vibrations and temperature changes can loosen fittings. Ensure all connections remain tight to prevent leaks.

- Replace When Necessary: If you notice any cracks or persistent leaks, it might be time to replace the fitting. Always opt for high-quality replacements to avoid frequent issues.

Consistent maintenance is the backbone of any reliable plumbing system. It not only saves you money but also keeps your home safe from water damage.

Troubleshooting Common Issues

Even with the best installation and maintenance, problems can arise. Here are some common issues and tips to solve them:

- Leaking Joints: If you notice water seeping from a joint, check the sealant and retighten the fitting. If the leak persists, disassemble and clean the joint before reapplying sealant.

- Corrosion: Corrosion can compromise the integrity of brass fittings. If you spot green or white deposits, clean them off and consider replacing the fitting if the corrosion is extensive.

- Noisy Pipes: Sometimes, fittings can cause pipes to vibrate or make noise. Secure the fittings and pipes with brackets or clamps to reduce movement.

By following these installation and maintenance tips, you can ensure your brass plumbing fittings perform optimally and last for years.

Cost and Availability of Brass Plumbing Fittings

Factors Affecting Cost

When it comes to brass plumbing fittings, the price can vary quite a bit. The cost is influenced by several factors, such as the type of fitting, its size, and the manufacturer. For instance, fittings made from high-quality red brass, which contains around 85% copper, might be priced higher due to their superior material properties. Additionally, specialized fittings or those with unique finishes may also fetch a premium price.

Where to Buy Quality Brass Fittings

Finding the right place to purchase brass fittings can make all the difference. Local hardware stores often carry a range of fittings, but for more specific needs, you might want to check out specialized plumbing suppliers or online marketplaces. These sources usually offer a wider selection and sometimes better prices. It’s important to compare prices and ensure that the fittings meet industry standards and certifications, especially if they’re for critical applications like potable water systems.

Balancing Cost with Quality

While it might be tempting to go for the cheapest option, it’s crucial to balance cost with quality. Cheaper fittings can lead to problems down the line, such as leaks or failures, which can end up costing more in repairs. Look for fittings that offer a good balance of price and durability. A well-made fitting may cost more upfront but will likely save money over time by reducing maintenance needs and increasing the longevity of your plumbing system.

Investing in quality brass fittings is not just about immediate savings, but ensuring the long-term reliability of your plumbing system. Choose wisely to avoid future headaches.

Conclusion

So, there you have it. Picking the right brass plumbing fittings isn’t just about grabbing the first thing you see on the shelf. It’s about knowing what you need and making sure it fits your specific situation. Whether you’re dealing with water, gas, or something else, brass fittings can be your best friend if chosen wisely. Remember to think about size, pressure, and compatibility before making a decision. And don’t hesitate to ask for help if you’re unsure. With the right choice, you’ll have a plumbing system that’s reliable and long-lasting. Happy fitting!

Frequently Asked Questions

What exactly are brass plumbing fittings?

Brass plumbing fittings are small parts used to connect pipes and fixtures in plumbing systems. They help manage the flow of water and other liquids.

Why should I choose brass fittings over others?

Brass fittings are strong, resist rust, and can handle high temperatures and pressures, making them a reliable choice for plumbing.

Where can I use brass plumbing fittings?

You can use brass fittings in various places like water pipes, gas lines, and even in heating and cooling systems.

How do I know which size brass fitting to buy?

Measure the outer diameter of your pipe and check the fitting size chart to ensure the right fit.

Are brass fittings easy to install?

Yes, brass fittings are generally easy to install and don’t require special tools, making them suitable for DIY projects.

What common mistakes should I avoid when choosing brass fittings?

Avoid mismatching sizes, ignoring thread compatibility, and choosing low-quality fittings to prevent leaks and other issues.